Introduction

In heavy industry, the manual handling of large-diameter pipes is a major bottleneck, posing significant safety risks and inefficiencies. Our recent project with Blue Sapphire Insuline Pvt. Ltd. demonstrates how targeted material handling automation provides a transformative solution.

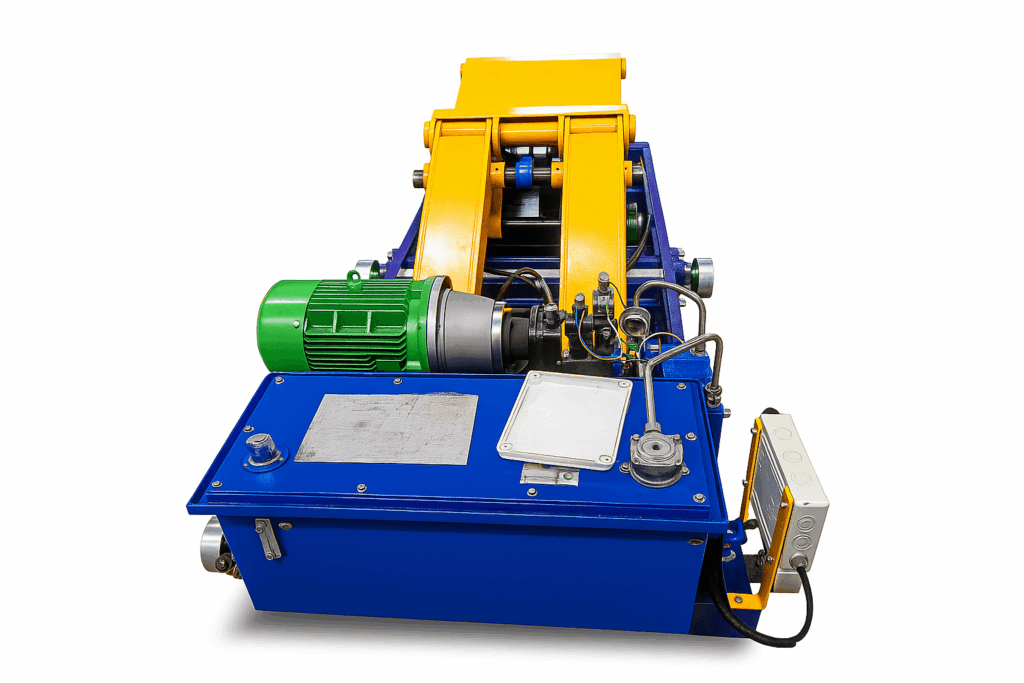

We engineered a custom Hydraulic Pipe Loading Buggy to tackle these challenges head-on. This case study explores how this solution enhances operational efficiency, reduces manual labor, and sets new safety standards, proving that automation is a necessity for forward-thinking manufacturing and steel plants.

The Industry Challenge: Why Specialized Equipment is Essential

The global construction equipment market is booming, driven by a need for efficiency improvements. However, industries like steel plants and fabrication yards face persistent issues:

- Safety Risks: High potential for musculoskeletal injuries and crushing accidents.

- Inconsistency and Damage: Improvised methods lead to pipe damage and production bottlenecks.

- Labor Intensity: Reliance on manual labor causes fatigue and reduces productivity.

The need for a robust, reliable, and safe mechanical handling solution was clear.

Our Engineered Solution: The Hydraulic Pipe Loading Buggy

Conceptualized as a floor-mounted, track-guided unit, our buggy was designed for reliability, power, and precision. It transports, elevates, and aligns heavy pipes from ground level to the required height with minimal operator effort.

Technical Specifications at a Glance

Parameter | Specification | Industry Benefit |

Material Handled | MS Pipes | Versatility for common industrial materials |

Pipe Diameter Range | Ø150 mm to Ø1980 mm | Unmatched capability for extremely large pipes |

Max. Weight Capacity | 7000 kg | Handles the heaviest loads with stability |

Lifting Height | 663 mm (Collapsed) to 1250 mm | Significant vertical range for flexible loading |

Drive System | 3 HP Geared Motor (Nord Make) | Reliable, controlled movement with high torque |

Lifting Power | Hydraulic Cylinder (100 bore x 800 stroke) | Smooth and powerful lifting operation |

Power Unit | 5 HP Motor, 75L Oil Tank | Robust energy source for continuous operation |

Key Features & Innovation Highlights

- Robust Construction with Premium Components:

The buggy’s base frame and pipe resting bed are built from Mild Steel (MS) with a protective powder coat. Critical stress points are reinforced with high-strength EN-8 steel pins and axles, ensuring integrity under full 7000 kg loads. - Superior Hydraulic System for Effortless Lifting:

The 5 HP power pack with a 75-liter oil tank ensures consistent performance. The 100mm bore hydraulic cylinder provides controlled force to elevate the maximum load smoothly and safely. - Precision Guided Mobility:

The buggy operates on a fixed track with Ø170 mm track wheels and high-quality SKF bearings, ensuring perfect alignment during transport and reducing operator skill requirements. - Centralized and User Friendly Control:

A dedicated control panel with intuitive controls allows a single operator to manage all functions effortlessly, enhancing workplace safety.

Tangible Customer Benefits: Beyond Specifications

The true value of this buggy is measured in the operational advantages it delivers:

- Enhanced Operator Safety: Eliminates manual lifting, drastically reducing the risk of injuries and enhancing site safety.

- Dramatic Productivity Gains: One operator can in minutes what used to require multiple workers, reducing downtime and accelerating timelines.

- Reduced Operational Costs: Minimizes manual labor, insurance premiums, and material damage costs.

- Unmatched Versatility: Handles a massive range of pipe diameters (150mm to 1980mm), supporting multiple projects.

- Improved Product Integrity: Controlled handling prevents pipes from being dropped or dented, reducing waste.

Applications Across Heavy Industries

This solution is suited for sectors handling large, heavy cylindrical loads:

- Steel Plants & Pipe Mills

- Heavy Engineering & Fabrication Workshops

- Infrastructure & Utility Projects

- Construction Equipment Manufacturing

Conclusion: Setting a New Standard in Industrial Handling

Our project with Blue Sapphire is a prime example of how engineering innovation solves industrial challenges. This buggy is a strategic tool that enhances safety, boosts productivity, and drives operational excellence.

It aligns with industry 4.0 trends prioritizing automation, workplace safety, and sustainable efficiency.

Is your operation still relying on manual methods to handle heavy materials? The future is automated, efficient, and safe.

Contact us today to discuss how we can engineer a customized material handling solution to revolutionize your productivity and protect your workforce.

Let’s build a safer, more efficient future together.