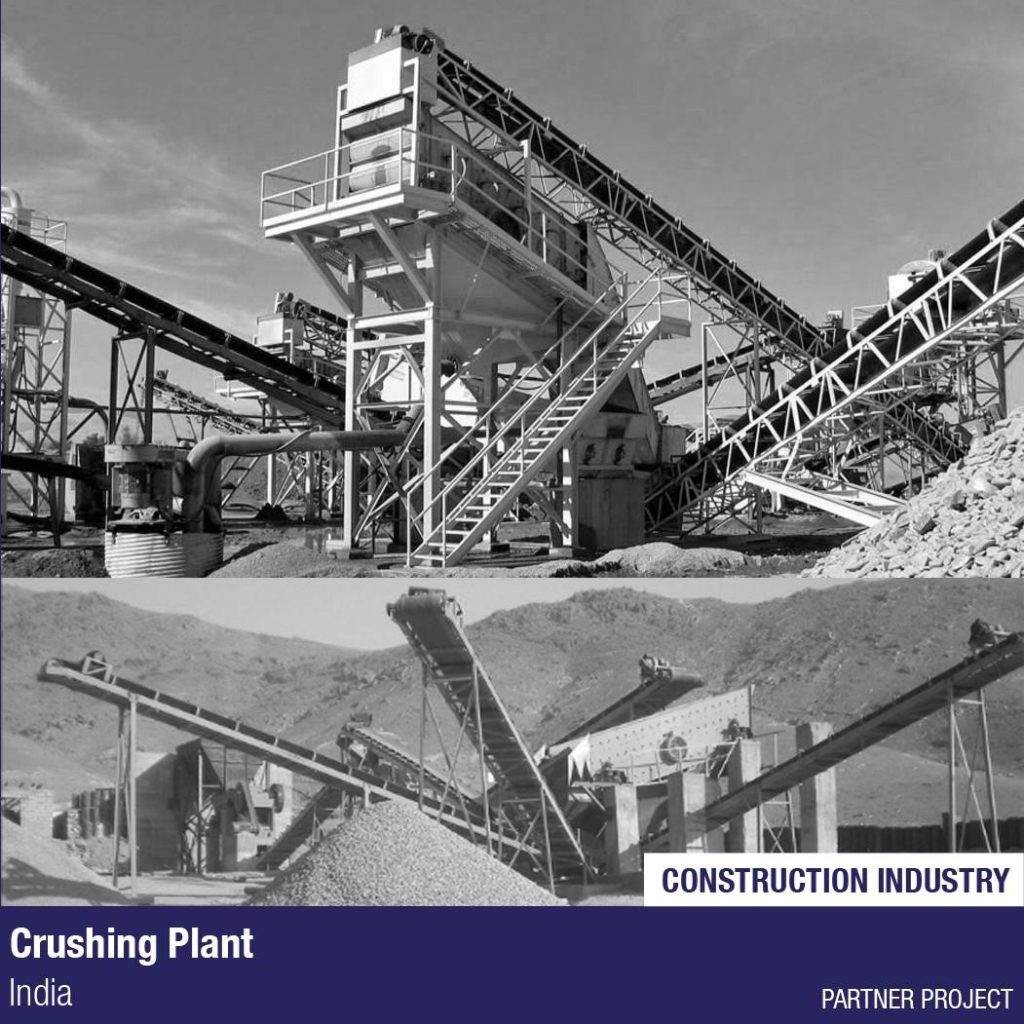

Efficiency and precision are paramount in the construction industry. Conveyor belt systems have revolutionized how raw materials are handled and transported during construction, providing unmatched efficiency, accuracy, and safety in material handling.

In the past, material transportation predominantly depended on manual labor or rudimentary mechanical equipment, often resulting in time-consuming and labor-intensive processes. However, this paradigm has shifted dramatically with the introduction of conveyor belt solutions.

At Dhanvanthri Engineers, we have seen numerous construction processes drastically affected by adding conveyors. This blog will explain how conveyor belt systems revolutionized the construction process and highlight their transformative impact on productivity, safety, and sustainability.

How Conveyor Belts Streamline the Construction Process

- Precise Material Handling: Conveyor belt systems ensure accurate and controlled handling of materials. By eliminating the need for manual adjustments, these systems enhance the quality and consistency of construction work, ultimately resulting in superior project outcomes. Moreover, these systems significantly reduce the likelihood of spillage during material transport, ensuring maximum utilization of resources and minimizing waste.

- Optimized Resource Utilization: Conveyor belt systems maximize resource utilization by facilitating the continuous material flow and minimizing idle time. Materials can be efficiently transported as needed, eliminating bottlenecks. This optimization improves resource efficiency, cost savings, and enhanced project performance.

- Better Accessibility: Conveyors have the significant advantage of being used in challenging terrain. For example, transporting large quantities of soil, gravel, and other materials across rugged terrain or environmentally sensitive areas may be necessary.

A Conveyor can be set up to traverse rough terrain, streams, or vegetation, allowing for the efficient transportation of materials without disturbing the natural landscape or requiring extensive earth-moving equipment. - Safety Advancement: Manual material handling tasks pose inherent safety risks for construction workers, including musculoskeletal injuries and accidents. Conveyor belts mitigate these risks by automating material transportation, reducing the need for heavy lifting and manual maneuvering.

Moreover, modular conveyor belt designs incorporate safety features such as emergency stop mechanisms and protective guarding, ensuring a secure working environment for construction personnel.

Defining the Environment Before Selecting the Conveyor belt

Environmental factors play a significant role in conveyor design and operation. Whether the project site is in a harsh climate, dusty environment, or corrosive atmosphere, the conveyor systems should be engineered to withstand these challenges.

Conveyor belt manufacturers must consider factors such as elevation, distance, dust exposure, and terrain, which are essential to consider while designing the conveyor. The materials and coatings should be carefully selected, ensuring reliable operation even in the most demanding conditions.

Designing the Conveyor According to the Material

Conveyor belts transport diverse materials essential for construction projects in construction raw material handling warehouses. These materials vary in size, shape, and composition and serve a specific purpose in the construction process.

The type of conveyor used depends on the material’s properties being transported via it. Manufacturers need to know the material’s volume, height, and texture to design the appropriate conveyor belt for their process.

For example, if the material transported is sticky, there is a risk of belt contamination with material spilling, potentially leading to costly maintenance or replacement. To address these challenges, the belt system often requires extra scrapers. These scrapers are positioned along the conveyor belt to remove sticky material buildup and prevent contamination, spillage, and tracking issues.

Designing the Conveyor According to the Project

Every construction project is unique, with distinct material handling needs, environmental considerations, and growth potential. Designing a conveyor for construction requires knowledge about the project. It is also essential to thoroughly analyze the project’s scope and objective to develop customized conveyor solutions that align perfectly with the project goals.

Let’s explore the Rock Handling System project in Vietnam to gain a deeper understanding.

Case Study

Our expert team implemented robust belt conveyors stretching over 200 meters to efficiently receive bulk materials from six-ton capacity front-end loaders. Our approach involved deploying various belt conveyor types, including flat, troughed, and inclined conveyors. Additionally, we integrated advanced components such as PLC control panels, weighing belts, and belt feeders to optimize operational performance and output. This comprehensive framework ensured seamless material handling and enhanced productivity throughout the project duration.

Read More: Rock Handling System, Vietnam

Expected Future Trends

Throughout our journey, our team has witnessed the transformative power of conveyor belt systems. As we look towards the future, we anticipate a paradigm shift in the approach of industrial conveyor system manufacturers in India. We envision a future where manufacturers adopt a more holistic approach to the industry, delivering comprehensive turn-key solutions that meet the evolving needs of various sectors.

We foresee conveyor systems manufacturers in India embracing a more customer-centric and forward-thinking approach. By understanding the unique characteristics of each sector, we foresee conveyor system manufacturers tailoring their solutions to effectively address industry-specific needs.

Conclusion

At Dhanvanthri Engineers, we lead the evolution of conveyor system manufacturing in India, setting the standard for quality, reliability, and innovation. Our commitment lies in delivering the highest caliber engineering products that meet and exceed industry standards.

Our belts and modular conveyor systems, tailored explicitly for the construction sector, are engineered to be dust-free, ensuring a clean and safe working environment. We take pride in the longevity of our products. With an extended lifespan of at least 10-15 years, they offer exceptional durability and value for our customers.

Furthermore, with a cross-industry approach, we offer superior products to minimize disruptions and optimize productivity. We go above and beyond just offering machines. We are shaping the future of conveyor belt solutions in India, driving innovation and excellence across industries.

Inspired to explore customized conveyor belt solutions for your project? Reach out to us today!

FAQs

What is the common problem of belt conveyors?

How do you prevent conveyor belt damage?

To prevent conveyor belt damage, regularly inspect the belt for signs of wear, tear, or damage and promptly address any issues. Additionally, avoid overloading the belt to prevent damage.

How do you control a conveyor belt?

Electrical motors, gears, and sensors typically control a conveyor belt, regulating its speed, direction, and stoppage. Electrical controls that adhere to safety and Good Manufacturing Practices (GMP) standards are essential for ensuring the smooth operation and maintenance of equipment. Programmable Logic Controllers (PLCs) and Variable Frequency Drives (VFDs) are commonly used to manage motor control effectively, enhancing efficiency and reliability in industrial processes.